Business

Introduction

Uniform Particle Sized

Ion Exchange Resins

Ion exchange resin is a resin with a uniform particle size of about 0.5-0.6mm in diameter, which is used to remove fine impurities including ions from water. It is used for various applications such as refining food and pharmaceuticals, water treatment, and the production of ultrapure water.

Advantages

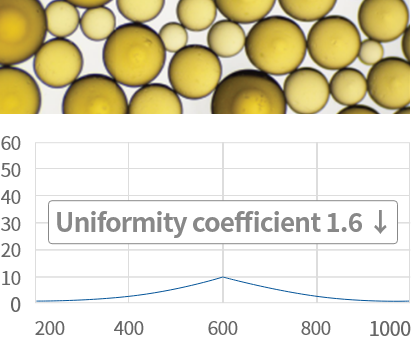

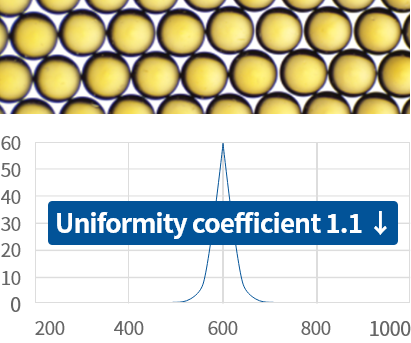

The highest level of uniformity

Samyang Fine Technology's Uniform Ion Exchange Resins boast the highest level of uniformity among existing ion exchange resins and achieve high performance due to the difference in uniformity. As it is produced uniformly in an optimized size, it enables fast and uniform reactions and maximizes operational exchange capacity by capably utilizing a charged effective resin bed. In addition, the physical and chemical strength improves leading to significantly reduced ion exchange resin fragmentation over long-term use.

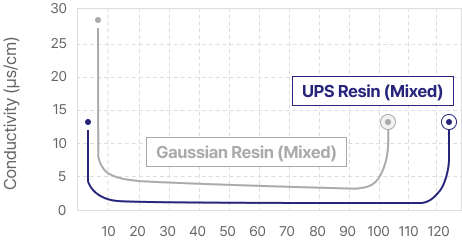

Comparison between conventional resin and uniform resin

Gaussian

(Conventional General Resin)

The reaction is uneven as conventional ion exchange resins do not have a uniform particle size.

Effective resin bed cannot be used efficiently

UPS

(Uniform Particle Sized Resin)

The reaction is constant as UPS resins have a uniform particle size.

Possible to use the effective resin bed efficiently.Advantages of using Uniform Particle Sized Ion Exchange Resins

- Fast reaction rates + Reduction of pressure drop + Excellent physical and chemical properties

- With high operational exchange capacity and quick processing water quality treatment, reduce leakage and increase the lifespan of ion exchange resins.

- Possible for economical operation and saving on the cost of equipment investment.

-

Specific Flow Rate (SV)

-

Specific Flow Rate (SV)

Production

Method

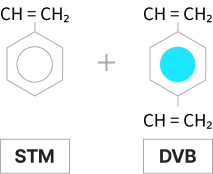

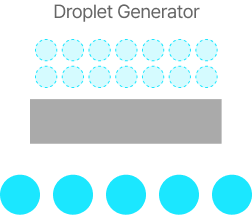

Droplet Generating

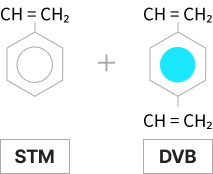

Samyang Fine Technology's uniform particle sized ion exchange resin is produced by advanced technology (Droplet Generating) which deviated from traditional mechanical sieving or polymerization methods. It is a premium-grade ion exchange resin produced in the world's most recently completed plant exclusively for uniform particle sized ion exchange resins. It is a next-generation ion exchange resin that satisfies strict quality standards with a uniform coefficient of 1.1 or less and has high physical and chemical durability.

Production method of

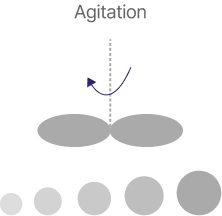

conventional

ion exchange resin

-

Adjustment of

raw materials

-

Polymerization process :

Agitation (stirring )

-

Post Treatment -

Introduction of an exchanger

- Packaging and shipping

Production method of

uniform particle sized

ion exchange resin

-

Adjustment of

raw materials

-

Polymerization process :

Droplet Generator

-

Post Treatment -

Introduction of an exchanger

- Packaging and shipping

Product

Ion Exchange Resins with versatile applications

Samyang Fine Technology's ion exchange resins are used not only to create ultrapure water for cleaning semiconductors or LCDs but also have a wide range of applications such as refining sugar syrup, separating and purifying bio-pharmaceuticals, treating water for nuclear power plants, and producing precision chemical catalysts. Its applications are very diverse, and demand is rapidly increasing.

Applicable

Areas

-

Water Treatment The water softening system and pure water production devices used for water treatment can be configured differently depending on the type of ion exchange resin filled in the resin tower, the layer, the direction of flow/regeneration, and the combination of various towers. It can be selected according to the corresponding raw water and treated water.More

-

Ultrapure Water Ultrapure water refers to pure water that has been treated through various water treatment processes to remove ionized/nonionized impurities. Electric and electronic industries, such as semiconductors and displays, have recently been developing cleaning processes which remove fine impurities. These processes have become more precise and are leading to stricter water quality requirements for ultrapure water.More

-

Chromatography TRILITE MCK Series is a resin utilized for chromatographic separation with a uniform particle size distribution of fine particles, and it can separate useful substances for various applications such as fructose/glucose separation, high-purity sugar separation as in the case of the recovery of sugar from molasses and acid purification, etc.More

-

Food Ion exchange resins used for food applications must be produced with strict management of impurities and foreign substances and must be handled as "Food grade" during import and export. In addition, it is necessary to obtain approval for food additives. For products intended for Islamic countries, HALAL certification is required.More